The ATLAS Shielding Project

The ATLAS Shielding Project

INDEX

Spain: Nortemecanica S.A

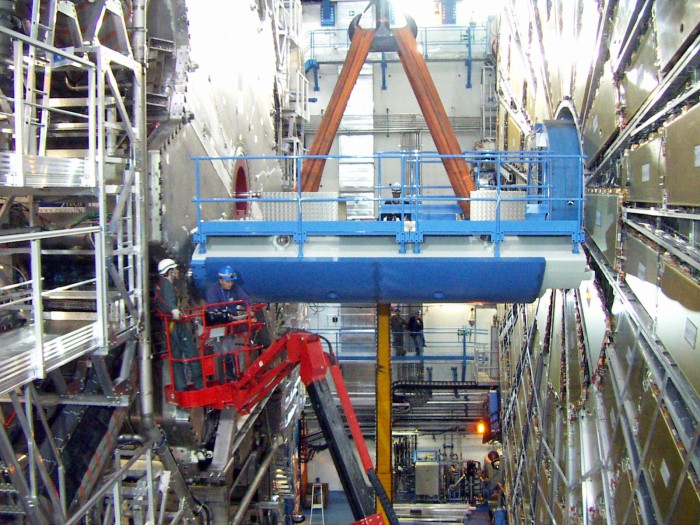

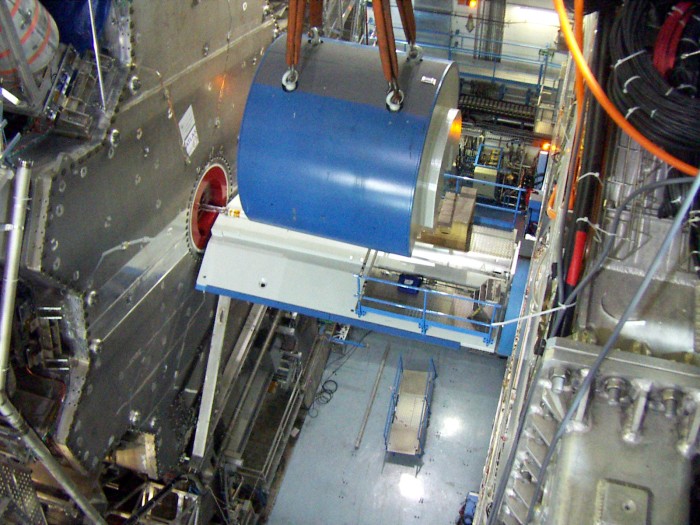

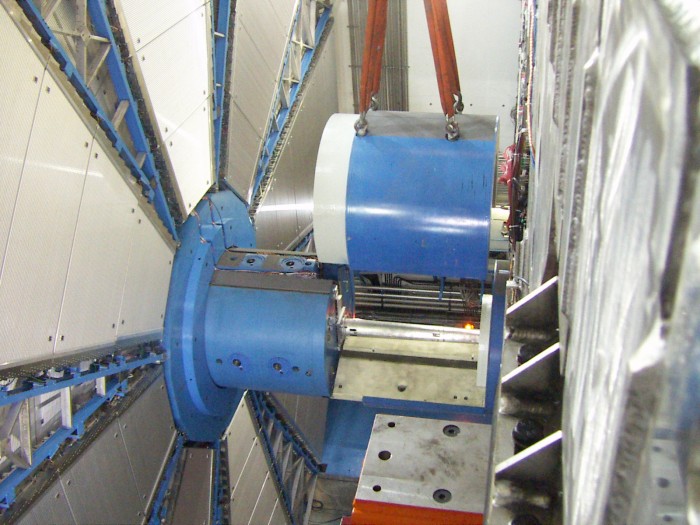

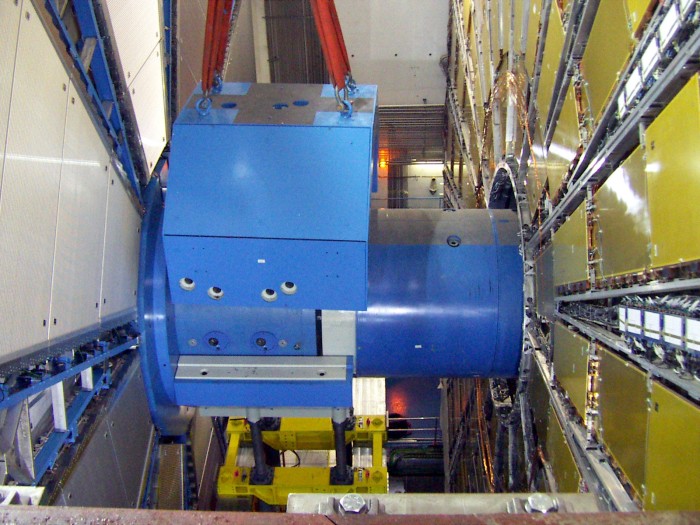

JFC1: 84 tonnes - 580 x 267 x 134 cm The JF Installation Installation plots by J. Palla. Click on a figure to get a high-resolution plot.

The JD/SW Installation

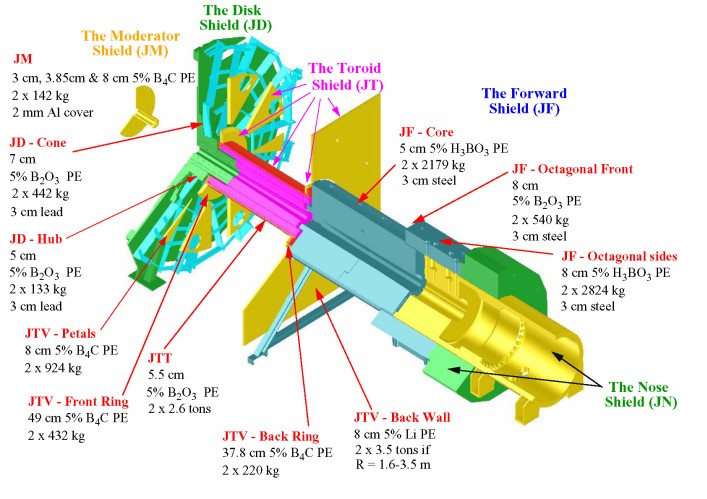

The JTV shielding consist of the

front wall (the "petals") made up of 8cm thick plates of polyethylene (Fig. 27)

doped with 5% (by weight) of boron carbide (B4C). These plates makes the

pattern on the ECT cryostat endplate that is shown in Figures 28 and 29. The outer

radius of the pattern is 347 cm.

Ideally the whole endplate should be covered by the shielding

but that is not possible due to a lack of space for it. Each of the two walls consist

of 16 different plates with a total weight of 924 kg.

In addition

to the front wall there is a front and back ring of doped polyethylene

as shown in the Figure above and in the Figures 30 and 31. The front

ring covers the radius 93 to 142 cm and it has a weight of 432 kg.

The back ring covers the radius 96.5 to 134.3 cm and has a weight of

220 kg.

A back wall made of 8 cm thick polyethylene has been

forseen as an upgrade project. It will be placed on the outside of the

cryostat between the ECT and the Big Muon Wheel. It will have to be

doped with lithium which produces less photons than boron since it

will not be possible to put up a photon filter in this region.

The JTT shielding is a cylindrical structure made of

ductile cast iron

that surrounds the beampipe in the endcap toroids (Fig. 32). The shielding

consists of four pieces called plug pieces, numbered 1 to 4 from the back (Fig. 34).

The front piece (plug 4) has a large hole in the center into which

the JD shielding will stick in. On the outside of the cast iron

is a polyethylene layer (Fig. 35) doped with B2O3 (5% by weight) which acts

as neutron shielding. The photons created in the polyethylene layer

are stopped by the stainless steel ECT bore tube that supports the

shielding.

The JTT shielding consist of 2x55=110 tonnes of cast iron

and 2x1.3=2.6 tonnes of polyethylene for a total weight of 113 tonnes.

The weight and size of the cast iron pieces are as follows:

PLUG 1: 13.2 tonnes - 118 x 160 x 160 cm

There are two parts:

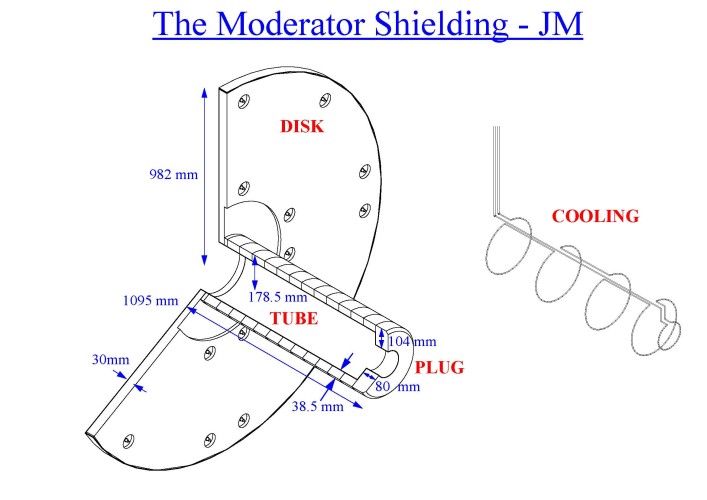

Both the disc and the tube/plug are covered by a 2 mm thick aluminium cover with a weight

of 5 kg and 21 kg respectively (Fig. 38 and 40).

The tube cover has water pipes on the inside for cooling during beampipe bake-out.

These cooling pipes are clearly seen in Figure 40. The shielding after installation

is shown as the black disc in Figure 41.

The disc was originally 50mm thick but the outer

20mm has been replaced by a layer of plastic scintillators thus reducing

the thickness to 30mm. Figure 42 shows three sectors of scintillators after

installation on the JM. The polyethylene is a fire hazard and the aluminium covers have

therefore been painted with a special white intumescent paint. This can be seen

in Figures 43 and 44 which shows the shielding after the covers have been installed

and painted.

Assembly drawings

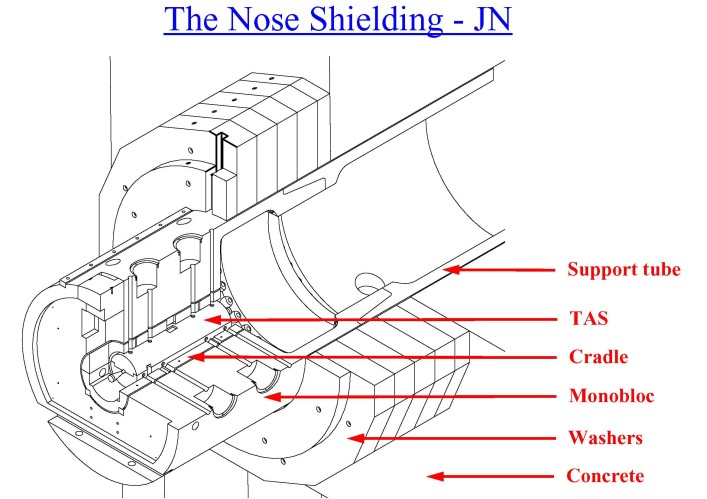

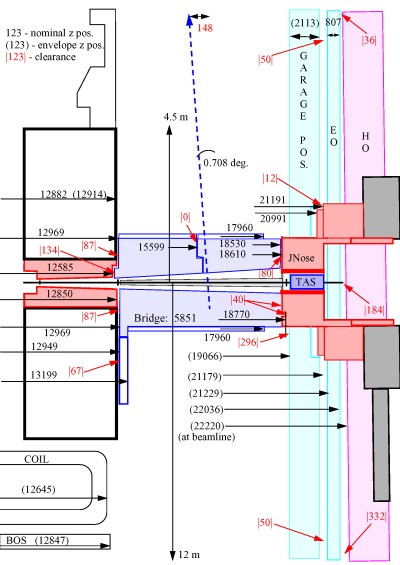

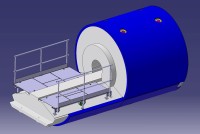

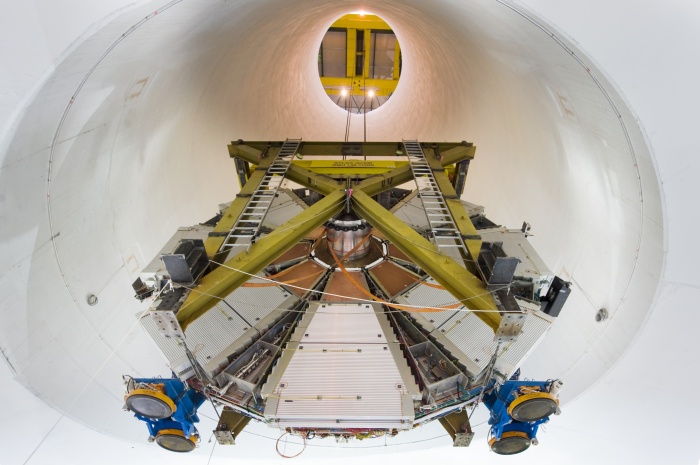

The main part of this shielding is the cylindrical 117 tonne heavy monobloc

(Fig. 48) that has an outer diameter of 295 cm. It is made of cast iron and it is

supported by a tube (Fig. 45) that is anchored in a 460 tonne concrete structure.

This cast iron tube has a weight of 51 tonnes and it has an inner diameter

of 257 cm and an outer diameter of 297 cm.

The 2x199 tonne heavy washers (Fig. 46) surrounds the tube and the monobloc.

They form a 201 cm thick structure in the beam direction.

There are six cast iron washers with washer no. 6 closest to the interaction point

and washer 1 attached to the concrete wall (Fig. 47). The inner diameter of

all washers are 301 cm. Washer 6 has a circular shape and the others are

16-sided to facilitate a future upgrade by adding cladding. The dimensions of the

washers are as follows:

The monobloc is bolted to the tube (Fig. 51). It has a 92.7 cm diameter hole

in the center for the TAS collimator (Fig 49.) and its cradle (Fig. 50).

The iron cradle (ID: 57.2 cm, OD: 87.2 cm and Weight: 5 tonnes) supports

the TAS and can be positioned with respect to the monobloc. The TAS is made

of copper, it is 180 cm long, has an outer diameter of 50 cm and an inner

diameter that is 3.4 cm. The weight of the TAS is about 3 tonnes.

Assembly drawings

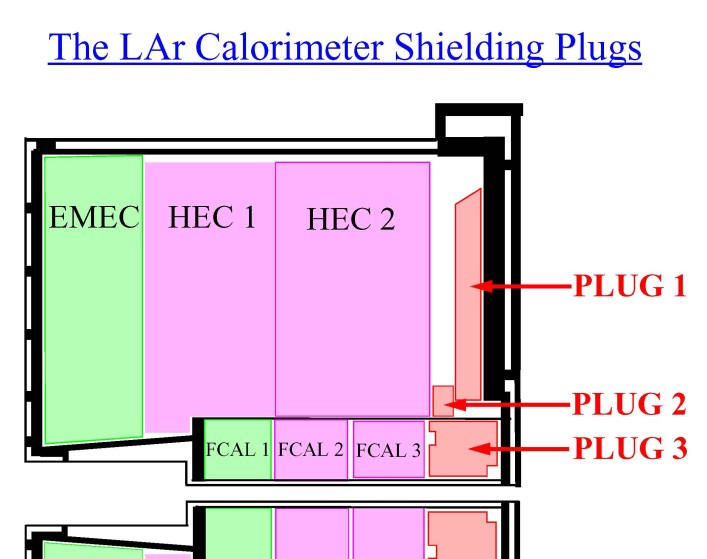

There is a smaller

ring shaped shielding called Plug 2 with a weight of 0.9 tonnes, an inner diameter

of 95 cm and an outer diameter of 135 cm (Fig 53).

Plug 3 sits at the back of the forward calorimeter as shown in Figure 54. It has

an inner diameter of 19 cm, an outer diameter of 90 cm and a weight of 3 tonnes.

Drawing of the LAr endcap calorimeter

The total weight of the shielding is 2825 tonnes. The table below shows how the mass (in tonne)

is distributed among the different shielding parts. In addition, there has been

support and tooling structures made with a total weight of 62 tonnes (JD Rotation frames - 4.2 tonnes,

JD Lifting frames - 36 tonnes, JF A-frames - 4.6 tonnes, JF lifting tables - 17 tonnes).

The last row in the table above shows reduction in tonnes of material due to final shielding design compared to

the one in the TDR.

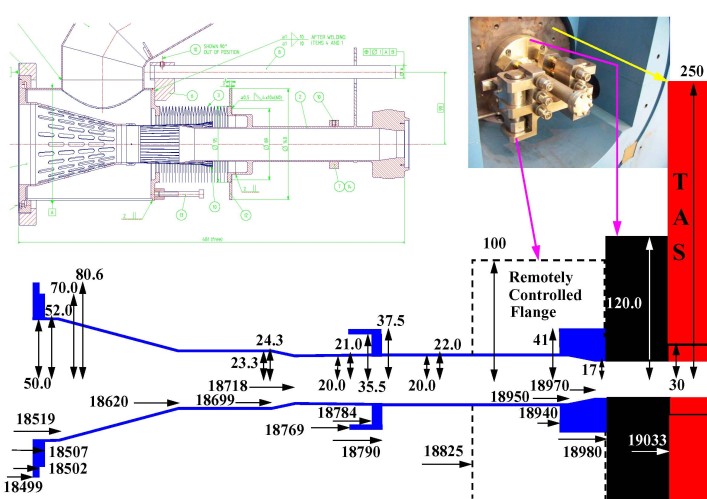

The pump in the VA beampipe

The connection between the VJ and the TAS beampipes

Hole in the shielding for the beampipe

JM Item Material Radius Z Thickness JM Disk lower

radius PE with 5% B4C 13.8-35 cm 351-352 cm 1 cm in z JM Disk upper

radius PE with 5% B4C 35-98.2 cm 351-354 cm 3 cm in z JM Tube PE with 5% B4C 14-17.85 cm 352-449.9 cm 3.85 cm in r JM Plug PE with 5% B4C 7.45-17.85 cm 449.9-457.9 cm 8 cm in z JM Disk cover Al 12.7-98.9 cm 350.8-351.0 cm 2 mm JM Plug cover

front Al 13.1-13.3 cm 352.0 444.2 cm 2 mm JM Plug cover

back Al 6.5-6.7 cm 444.2-457.7 cm 2 mm

LAr calorimeter - JD

JD Item Material Z Radius Thickness JD Disk - small Grey

steel 677.9-682.9 cm 75-270 cm 5 cm in z JD Disk - large Grey

steel 682.9-690.9

cm 54 436

cm 8 cm in z JD Tube Stainless

steel 678.4-888.9

cm 43-53

cm 10

cm in r JD Plug - front Brass

678.4

cm 13-42

cm 29

cm in r JD Plug - back Brass 886.4

cm 16.9-42

cm 25.1

cm in r JD Hub - front Brass 716.9

cm 54-76.41

cm 22.41

cm in r JD Hub - back Brass 786.9

cm 54-85

cm 31

cm in r JD Hub cladding PE + 5% B2O3

+ Pb 7

cm + 3 cm JD Cone cladding PE + 5% B2O3

+ Pb 5

cm + 3 cm

JD - JTT

JT Item Material Z Radius Thickness JTT Plug JD hole Ductile

iron 811.4 890.9

cm 60.0-80.2

cm 20.2

cm in r JTT Plug VT

hole Ductile

iron 890.9

cm 17.1-80.2

cm 63.1

cm in r JTT Plug VT hole Ductile

iron 1258.5

cm 24.2-80.2

cm 56.0

cm in r JTT Plug JF

hole Ductile

iron 1258.5-1285.0

cm 56.25-80.2

cm 23.95

cm in r JTT poly PE

+ 5% B2O3 818.1-1285.0

cm 80.2-85.7

cm 5.5

cm in r Toroid bore tube Stainless

steel 792.9-1288.2

cm 87.25-91.25

cm 4.0

cm in r JTV Front Ring PE

+ 5% B4C 805.9-821.9

cm 93-142

cm 16 cm in z, 49 cm in r JTV Back Ring PE

+ 5% B4C 1261.7-1275.7

cm 96.5-134.3

cm 8 cm in z, 37.8 cm in r JTV Front wall PE

+ 5% B4C 799.9-807.9

cm ca

145-345 cm 8 cm in z, 200 cm in r JTV Back Wall PE

+ 2.7 % Li 1288.2-1296.2

cm 160-350

cm 8 cm in z, 190 cm in r

JTT - JF

JF Item Material Z (cm) Inner Radius Outer Radius Thickness A frame Stainless

steel 1294.9-1319.9 Bridge - front Ductile

iron 1296.9

cm 26.7

cm 147

cm 119.1

cm in r Bridge - back Ductile

iron 1857.0

cm 30.8

cm 147

cm 111.4

cm in r Bridge back ledge Ductile

iron 1857.0-1877.0 43.8

cm 58.8

cm 15.0

cm in r Bridge cladding PE

+ 5%H3BO3 + Fe 1296.9-1796.0 147.4

cm 155

cm 4.6

cm + 3 cm JFC2 front nose Ductile

iron 1271.9-1296.9 28.0

cm 147

cm 121

cm r, 25 cm z JFC2 front Ductile

iron 1296.9

cm 28.2

cm 147

cm 118.8

cm in r JFC2 back Ductile

iron 1559.9

cm 30.2

cm 147

cm 116.8

cm in r JFC2 back nose Ductile

iron 1559.9-1579.9 30.3

cm 85

cm 54.7

cm r, 20cm z JFC2 cladding PE

+ 5%H3BO3 + Fe 1296.9-1559.9 147.4

cm 155

cm 4.6

cm + 3 cm JFC3 front bore Ductile

iron 1559.9-1579.9 89.0

cm 147

cm 58

cm r, 20 cm z JFC3 VJ hole Ductile

iron

1579.9 cm 30.4

cm 147

cm 116.6

cm in r JFC3 - back Ductile

iron 1853.0

cm 35.6

cm 147

cm 111.4

cm in r JFC 3 cladding PE

+ 5%H3BO3 + Fe 1559.9-1796.0 147.4

cm 155

cm 4.6

cm + 3 cm Octagonals Ductile

iron 1810-2099

cm 150.0

cm 199

cm 49

cm in r front cladding PE

+ 5%B2O3 + Fe 1799-1810

cm 150.0

cm 210

cm 8

cm + 3 cm in z side cladding PE + 5%H3BO3 + Fe 1810-2099 cm 199 cm 210

cm 8

cm + 3 cm in r

JF - JN

JN Item Material Z Radius Thickness TAS Copper 1903-2083

cm 3-25

cm 22.5

cm in r Cradle Ductile

iron 1867-2087.5

cm 28.6-43.6

cm 15

cm in r Monobloc front Ductile

iron 1861-2089.5

cm 46.35-147.5 101.15 cm in r, 228.5 cm in z Monobloc middle Ductile

iron 2089.5-2196.5

cm 128.5-147.5

cm 19

cm in r Monobloc back Ductile

iron 2196.5-2205.5

cm 108.5-147.5

cm 39

cm in r Monobloc + Tube Ductile

iron 2205.5-2286.5

cm 108.5-148.5

cm 40

cm in r Tube front Ductile

iron 2286.5-2306.5

cm 108.5-148.5

cm 40

cm in r Tube back Ductile

iron 2306.5-2605.5

cm 128.5

-148.5 cm 20

cm in r Washers -

front Ductile

iron 2099.1-2119.1

cm 150.5-207.5

cm 57 cm in r, 20 cm in z Washers - back Ductile

iron 2119.1-2300

cm 150.5-262

cm 111.5 cm in r, 180.9 cm in z Concrete -

left Concrete 2300-2640

cm 148.5-422

cm 273.5 cm in r, 340 cm in z Concrete -

right Concrete 2300-2580 cm 148.5-422 cm 273.5 cm in r, 280 cm in z

The old shielding web-pages are available here.

Responsible for the content of this page is

Vincent Hedberg

Contact persons for JM, JD, JT and JF: Vincent Hedberg (Project Leader)

and Jan Palla (Project Engineer)

Contact person for JN: Francois Butin

Contact person for LAr plugs: Leif Shaver

Institutes

Suppliers

Introduction

Shielding elements

JF - The forward shielding

JD - The disk shielding

JT - The toroid shielding

JM - The moderator shielding

JN - The nose shielding

Plugs in the LAr calorimeter

Cladding

Materials

Positions and dimensions

Status

Workpackages

INSTITUTES PARTICIPATING IN THE PROJECT

CERN (Switzerland)

Yerevan Physics Institute (Armenia)

Institute of Physics, University of Belgrade (Serbia)

Institute of Experimental and Applied Physics, Czech Technical University in Prague (The Czech Republic)

Institute of Particle and Nuclear Physics, Charles University in Prague (The Czech republic)

Department of Experimental High-Energy Physics, Lund University (Sweden)

Department of Physics, University of Arizona (USA)

People

SUPPLIERS TO THE ATLAS SHIELDING PROJECTS

Bulgaria: Heavy Machinebuilding

Germany: Hunger Hydraulik

& Siempelkamp

Italy: SIMIC S.p.A.

The Slovak Republic: JAMP sro & Slovmetal sro

Serbia: LOLA SISTEM & Kryoprema

Armenia: Energocomplex

The Czech republic:

Tranza AS &

Skoda Hute sro &

Kopos Kolin AS &

FEST Ostrava sro &

RADL sro &

Stampa Ostrava sro

Switzerland:

AGI AG Zurich &

Mantrade Fordertechnik AG &

Bossard &

Bachofen AG &

Spanset SA &

Matec Soudure Sarl &

ARSA Aciers Romands SA &

Bischof SA &

Friderici SA &

AMC Technologies SA &

Bruetsch/Ruegger AG

France:

Farba Sarl &

Gonzales SA &

Roger Colin SAS &

SCMR &

STAS Sarl &

Pivicat SA &

SAMSE &

SVH &

BVM Sarl &

A2S

Pakistan: Heavy Mechanical Complex 3 (HMC3)

Australia: VEEM Engineering

Belgium: Resarm SA

Greece: TEMKA SA

INTRODUCTION

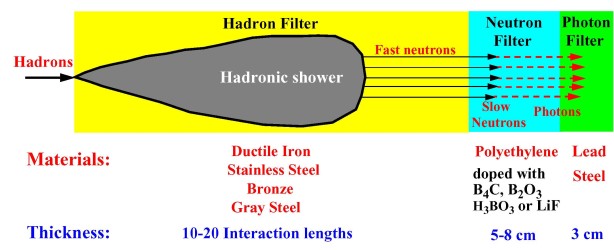

The very high energy and collision rate at the LHC means that the levels of low-energy neutron,

high-energy hadron and photon radiation are at an extremely high level in the ATLAS experiment.

This causes several problems such as radiation damage to detectors and electronics and background

signals resulting in enhanced trigger rates in some of the detector systems such as the muon detector.

The high radiation levels also cause

activation of certain detector elements

with the result that some maintenance

operations will become difficult due to radioprotection considerations.

The main problem is not caused by the particles originating from the interactions but from secondary

particles created in hadronic showers in the beampipe, forward calorimeter and the TAS collimator.

The purpose of the shielding in ATLAS is to reduce the number of background particles in the Inner

Detector and the Muon spectrometer to a manageable level and to

protect people working in the electronics cavern (USA15).

Since different types of radiation

require different types of shielding materials, a multi-layered shielding approach is used in ATLAS.

The inner layer has as a purpose to stop high energy hadrons and its secondaries. This layer is made

of material which gives a large number of interaction lengths such as iron or copper.

In the case of iron, studies have shown that a minimum carbon content of a couple of percent is

advantageous since it moderates the neutron energy down to lower values. A second layer,

consisting of doped polyethylene, is used to moderate the neutron radiation escaping from

the first layer and the low energy neutrons are then captured by a dopant (either boron or lithium).

Photon radiation is created in the neutron capture process and these photons are stopped in the

third shielding layer which consists of steel or lead. Lead is more effective in stopping photons

but it has the disadvantage of giving off more neutron radiation than steel.

The shielding physics is discussed further in

chapter 2 of the

ATLAS Radiation Taskforce Report.

Massive simulations have been carried out by the

ATLAS Radiation Task Force

during several years in order to optimize the effectiveness

of the shielding in ATLAS. This optimization process is discussed in

chapter 8

of the

Radiation Taskforce Report. Tables with more detailed results are presented

on a separate

web site.

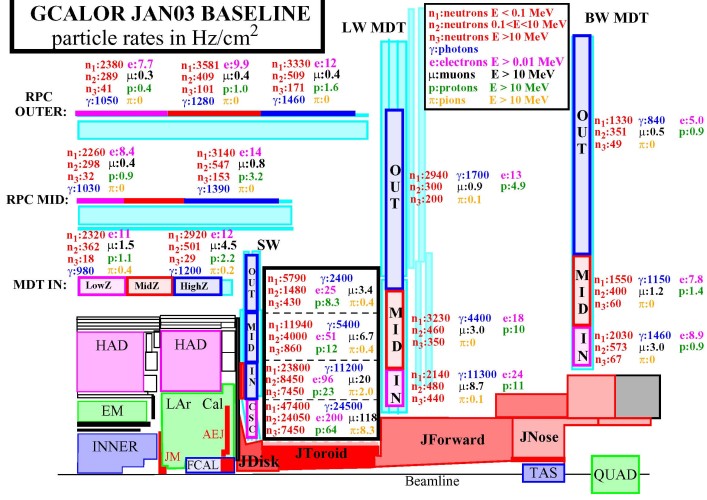

The background radiation that

can be expected with the shielding has been calculated and is shown in the Figure above.

More detailed tables and plots are available on a separate

web site.

DESCRIPTION OF THE SHIELDING ELEMENTS

The shielding in ATLAS is divided up in the six subprojects that are illustrated in the figure

above. The drawings of the shielding elements are all on

CDD. In order to find the folders with

only the latest up-to-date drawings select the "Folders" option in CDD and then enter the search

terms JF%, JD%, JM%, JN% or JT%. This will give lists of folder with only up-to-date drawings.

The subproject are described below.

The ATLAS shielding is described in the large ATLAS detector paper

2008 JINST3 S08003.

The status of the shielding project at the end of 2008 is described in the EDMS document

ATL-J-EN-0008.

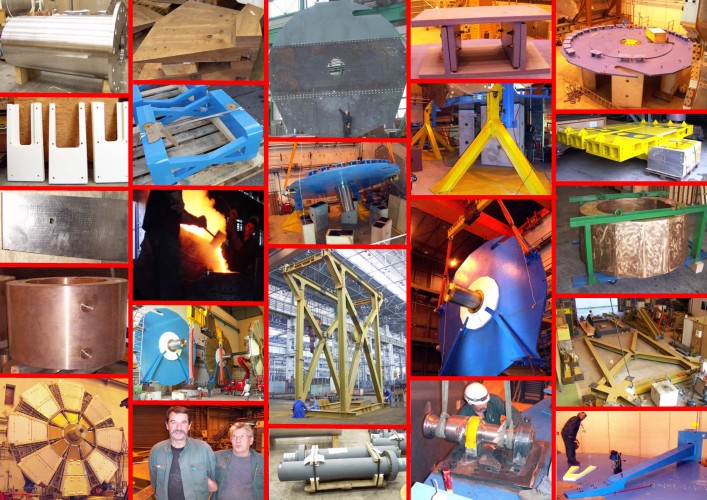

Fig 1. The ductile cast iron pieces for the core part.

Fig 2. Polyethylene bricks are being assembled for the cladding.

Fig 3. The outer steel plates after manufacturing.

Fig 4. The bridge section arrives at CERN.

Fig 5. JFC1 and JFC2.

Fig 6. The core part is being assembled at CERN.

Fig 7. One of the octagonal upper pieces arrives at CERN.

The purpose of the two Forward Shielding assemblies (JF) is to protect the big muon wheel and the muon

EO chambers from background particles created in secondary interactions in the beampipe,

the calorimeters and the TAS collimators. This shielding is removable and will be stored

in the surface building during maintenance of ATLAS. The shielding consists of two parts:

The cylindrical core and the octagonal back. Three pieces called JFC1 ("the bridge"),

JFC2 and JFC3 are used for the core and two pieces called "JFS3 upper" and "JFS3 lower"

for the octagonal back.

All pieces are made of

cast ductile iron

(Fig. 1) surrounded by a layer of polyethylene doped

with boron followed by a 3 cm thick steel layer (Fig. 3). The ductile iron has a large carbon

content and the carbon acts as a moderator of the neutron radiation. The core pieces have

a 5 cm thick polyethylene layer and an 8 cm thick layer is surrounding the

octagonal pieces. These polyethylene layers are made of 10,000

bricks

(Fig. 2) with

three different shapes. The polyethylene is rich on hydrogen which will slow down (moderate)

the neutrons. The polyethylene also contains 5% of boron by weight in the form of H3BO3.

This boron has a large absorption cross section for thermal neutrons.

The outermost steel layer stops the photons created when the neutron radiation is

absorbed by the boron.

The bridge section is supported at the front by the stainless steel A-frame with

a weight of 2.3 tonnes and at the back by a ledge in the JN monobloc (Fig. 51).

The A-frame was load tested in Serbia to 173 tonnes before delivery. After modifications at CERN,

it was re-tested to 189 tonnes (Fig. 12) on the 15th of April 2008. The deformation of both A-frames

was 11 mm.

JFC2 and JFC3 are supported by the bridge section. The total

weight carried by the A-frame and the ledge in the monobloc is 275 tonnes. Figure 11

shows how the lower octagonal piece is supported by a 8.5 tonnes heavy hydraulic lifting table

(Fig. 10) that is positioned on top of the HF truck. The upper octagonal pieces rest on the

lower piece. The weight

of the two octagonal pieces is 143 tonnes. The stroke of the jacks (Fig. 13) in the lifting table is

130 cm and each jack can lift 120 tonnes i.e. the lifting table is designed to carry a

total weight of 480 tonnes (in case the monobloc cannot take the weight of the core

the lifting table is designed to take the weight of both the core and the octagonals).

The JF shielding consist of 2x387=775 tonnes of cast iron, 2x24=50 tonnes of steel plates

and 2x5.5=11 tonnes of polyethylene for a total weight of 2x418=836 tonnes.

The weight and size of the pieces are as follows:

JFC2: 93 tonnes - 308 x 310 x 232 cm

JFC3: 98 tonnes - 293 x 310 x 232 cm

JFS3U: 77 tonnes - 420 x 300 x 246 cm

JFS3L: 66 tonnes - 420 x 300 x 212 cm

Assembly drawings

Drawings of the large cast iron pieces

Drawings of the polyethylene layer

Drawings of the steel plates

Drawings of the A-frame

Drawings of the lifting table

Technical Specifications

FEA calculation reports and SC approvals

Webcam of forward shielding on side A in ATLAS

Webcam of forward shielding on side C in ATLAS

More JF photos

Fig 8. A lower octagonal piece is being unloaded.

Fig 9. The octagonal pieces after assembly.

Fig 10. The JF lifting table with its 4 hydraulic jacks in grey.

Fig 11. The lifting table when it supports the lower octagonal piece.

Fig 12. The A-frame is being load tested.

Fig 12. The A-frame is being load tested.

Fig 13. The hydraulic lifting jacks for the JF lifting table.

Installation Manager: Raphael Vuillermet

Report ATL-JF-IP-0001:

Installation of the forward shielding - V. Hedberg

TMB presentation - 13 March 2008:

JF Shielding Modifications and Installation - R. Vuillermet & D. Mladenov

ATLAS week presentation - 7 April 2008:

Installation of the forward shielding and LUCID

(Video) - V. Hedberg

Magnet workshop - 15 April 2008:

Forces between magnets and shielding - W. Kozanecki

Magnetic field meeting - 30 April 2008:

Forces between magnets and shielding during installation - A. Vorozhtsov

PPSPS - 22 May 2008: Installation of the JF shielding - P. Petit

Report ATL-HT-OP-0008 - 26 September 2008: Procedure for the installation of the Forward Shielding - P. Petit

Report ATL-HT-OP-0009 - 26 September 2008: Procedure for the dismantling of the Forward Shielding - P. Petit

Action lists from the JF installation meetings (by R. Vuillermet):

24 January 2008 -

30 January 2008 -

7 February 2008 -

14 February 2008 -

21 February 2008 -

28 February 2008 -

6 March 2008 -

13 March 2008 -

20 March 2008 -

3 April 2008 -

10 April 2008 -

16 April 2008 -

29 April 2008 .

Installation of JFC1 on side C -

Photos

Video

Installation of JFC1 on side A -

Photos

Installation of JFC2 on side C -

Photos

Video

Installation of JFC2 on side A -

Photos

Installation of JFC3 on side C -

Photos

Video

Installation of JFC3 on side A -

Photos

Removal of JFC1 using the lifting table -

Photos

Video

Installation of JFS3 on side A -

Photos

Video

Installation of JFS3L on side C -

Photos

Video

Installation of JFS3U on side C -

Photos

Video

Fig 14. The disc pieces during manufacturing.

Fig 15. The stainless steel tube that supports the plug pieces.

Fig 16. One of the four plug pieces that sits in the tube.

Fig 17. The ring segments are being assembled.

Fig 18. One of the ring segments.

Fig 19. A rib piece is being attached.

Fig 20. Installation of cone pieces.

Fig 21. The polyethylene and lead cladding is attached to

the cone pieces.

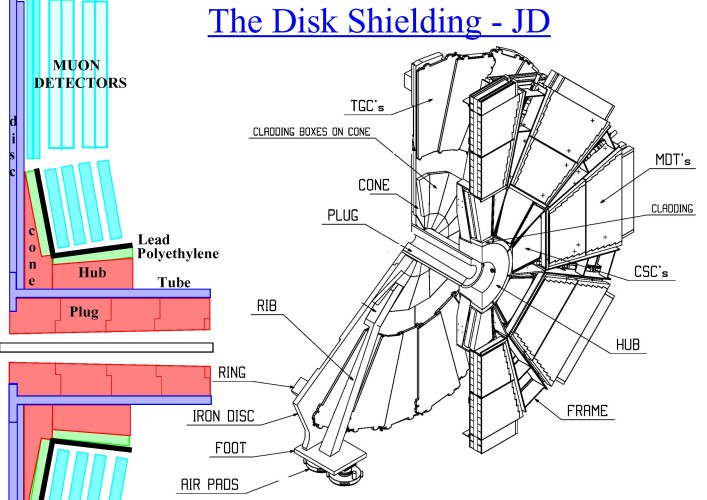

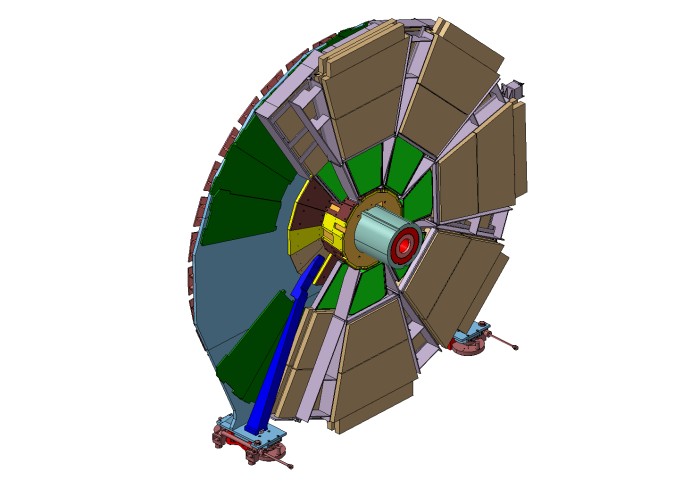

The Disk Shielding (JD) has a threefold purpose: It supports the muon

chambers in the first forward muon station (the Small Wheel), it shields

these chambers from radiation and it returns the magnetic field from the

solenoid magnet in a well defined way. The various parts of the disk shielding

are shown in the figure above. The largest pieces are the five plates

that make up the disc itself (Fig. 14). Three of these are used for the 8 cm thick

"large disc" with a diameter of 872 cm and two for the 5 cm thick "small disc"

which has a diameter of 540 cm. The two cast iron ribs (1.6 tonnes) that are attached to

the large disk are used to increase the mechanical stability of the JD (Fig. 19 & 25).

31 ring segments (Fig. 17 & 18) with a weight of 161 kg each are attached to the large disk.

The purpose of these

ring segments are to lead the magnetic field back through the electronic boxes

("the drawers") of the Tile calorimeter. One ring segment will cover

two Tilecal drawers. The size of the ring segments can be adjusted in the

z-direction from 270 to 340 mm.

A 208 cm long and 5.4 tonne heavy stainless steel tube (Fig. 15) with a diameter of 106 cm is

attached to the center of the large disc. It is filled with 4 brass plug

pieces (Fig. 16) with a total weight of 8.3 tonnes. All the leaded red brass pieces

(UNS C83600)

in the shielding of ATLAS consists of 85% Cu, 5% Pb, 5% Sn and 5% Zn.

The purpose of the plug is to shield the muon chambers from background

radiation created by interactions in the beampipe and forward calorimeter.

The brass cone pieces (Fig. 20) have the same purpose as the plug. They are covered

by a cladding consisting of a 70 mm thick polyethylene layer doped with 5% (by weight)

of B2O3 followed by a 30 mm thick lead layer

(UNS L52901)

(Fig. 21). The weight of one cone assembly

is 5.4 tonnes (brass) + 442 kg (polyethylene) + 2.1 tonnes (lead).

The 70 cm long hub piece (Fig. 22) is made of brass with a measured density

of 8.44+-0.04 g/cm3. It supports the Small Muon wheel

with its CSC and MDT chambers and it can slide on the tube with the help

of a rail system on the top. In this way the Small Wheel detectors can be serviced

from both sides. This also makes it possible to reach the TGC detectors that are

attached to the disc. The hub has a cladding consisting of a 5 cm thick B2O3 layer (Fig. 23)

and a 3 cm thick lead layer. The total weight of the hub (including cladding)

is 8.4 tonnes. Of this 133 kg comes from the polyethylene and 1.1 tonne from the lead.

The finished JD shieldings (Fig. 24 & 25) have a diameter of 872 cm and a total

weight of 2x87=174 tonnes. The total weight of the muon chambers is about 13 tonnes

(SW 12 tonnes and TGCs 1 tonne) which

brings the total weight of one JD/SW assembly to 98 tonnes. The chambers also increase

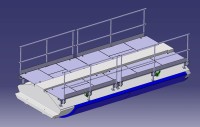

the diameter to 930 cm. A special installation frame (Fig. 26) has been build to

transport the JD/SW assembly. This frame has a weight of 18 tonnes and so the total

weight of JD + SW + Frame is 116 tonnes. If the JF hydraulic jacks are used in combination

with the lifting frame that will add another 17 tonnes for a total weight of 133 tonnes.

Assembly drawings

Drawings of the steel disk

Drawings of the stainless steel tube

Drawings of the brass plug

Drawings of the brass cone and the polyethylene & lead cladding

Drawings of the cast iron ribs

Drawings of the steel ring pieces

Drawings of the feet

Drawings of the brass hub and the polyethylene & lead cladding

Drawings of the installation frame

Drawings of the tooling for the rotation

Drawings of the hub movement system

Drawings of the JD lifting beam

Drawings of the load test beam

Drawings of building 191

Webcam in building 191

Technical Specifications

FEA calculation reports and SC approvals

Trench in SX1 - Engineering change request

Increased length of JD tube - Engineering change request

Fig 22. The hub piece that supports the Small Wheel.

Fig 23. Two of the polyetylene pieces used in the cladding on the hub.

Fig 24. The front of the JD shielding (the IP side).

Fig 25. The back of the JD shielding.

Fig 26. The lifting frame that is used to transport the JD/SW assembly.

More JD photos

Installation Manager: Patrick Petit

Installation review on JD/Small Muon Wheel - 10 may 2006

Review of the installation of the small wheels - 8 October 2007

TMB presentation - 31 January 2008

JD/SW installation note

PPSPS notes for the JD/SW installation

Note describing the JD movement procedure on the rails

Dynamic conflict study: Report - Video (15 Mb in wmv-format)

Video of the closing of the small wheel on the JD.

(11Mb file in wmv-format)

Video of one of the loadtests of the JD installation frame.

(26Mb file in wmv-format)

Video of the first transport of the JD/SW to ATLAS.

(72Mb file in wmv-format)

Video of the installation of JD/SW-C in ATLAS.

(27Mb file in wmv-format)

The media event on the 29:th of February 2008.

Fig 27. A JTV petal segment in the front wall.

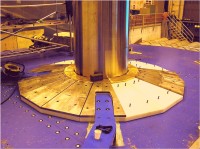

Fig 28. The JTV petals are being installed on the endcap toroid endplate.

Fig 29. The endcap toroid endplate after installation of all petals.

Fig 30. The pieces making up one of the JTV rings.

Fig 30. The pieces making up one of the JTV rings.

Fig 31. One of the two JTV rings.

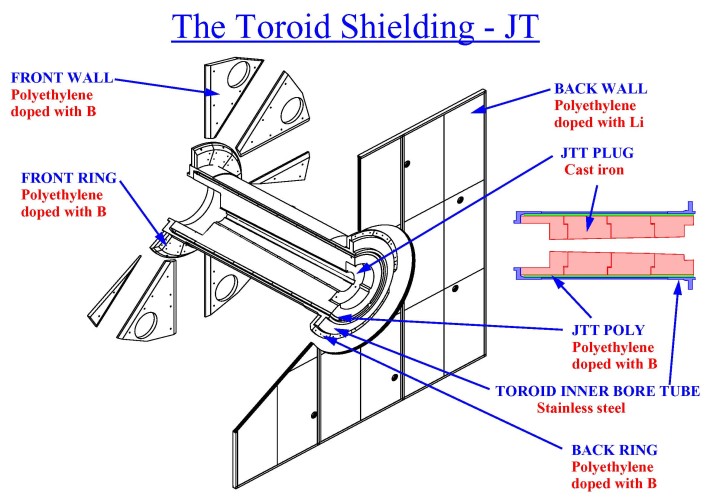

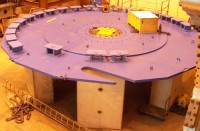

The toroid shielding consists of two parts: JTT which surrounds

the beampipe and JTV which is neutron shielding situated inside

the endcap toroid cryostat. The purpose of the JTV shielding is

to moderate neutron radiation and then to stop the low-energy

neutrons by absorption in boron. The photons created in this process

are stopped by the ECT cryostat.

PLUG 2: 15.5 tonnes - 128 x 160 x 160 cm

PLUG 3: 15.5 tonnes - 128 x 160 x 160 cm

PLUG 4: 11.0 tonnes - 128 x 160 x 160 cm

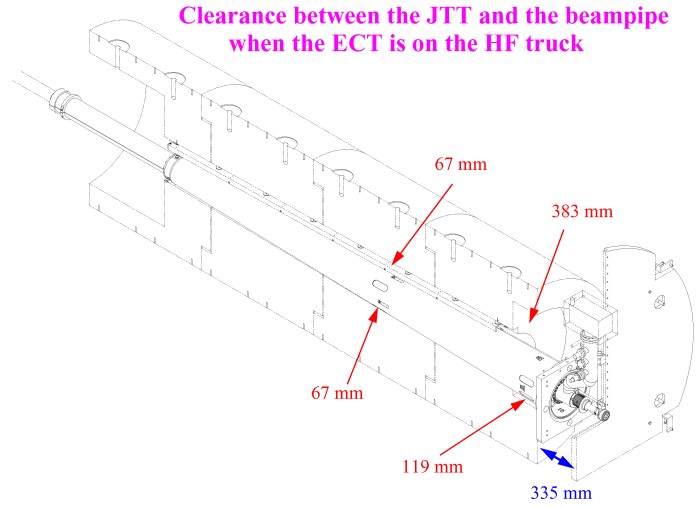

The overall length of the JTT shielding is 473.6 cm (Fig.33).

The polyethylene layer is 55 mm thick i.e. the diameter of the

JTT after assembly is 171 cm (the diameter of the ECT bore tube is 174.5 cm

and its length is 495.3 cm).

Assembly drawings of the shielding around the beampipe (JTT)

Assembly drawings of the shielding inside the toroid vacuum vessel (JTV)

Drawings of the cast iron cylinder surrounding the beampipe

Drawings of the polyethylene cladding on the iron cylinder

Drawings of the polyethylene petals on side A

Drawings of the polyethylene petals on side C

Drawings of the polyethylene ring on the IP side

Drawings of the polyethylene ring on the non-IP side

Technical Specifications

FEA calculation reports and SC approvals

Change of brass to iron in JTT plug - Engineering change request

More JT photos

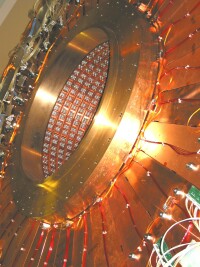

Fig 32. The ECT cryostat. The JTT is installed in the hole in the center.

Fig 33. Test assembly of the JTT plug pieces.

Fig 34. The final JTT ductile iron core pieces.

Fig 35. The JTT polyethylene cladding.

Fig 36. The JTT shielding while it was stored in the old UA1 shaft.

Fig 37. Half of one JM disc.

Fig 38. The aluminium cover for the disc.

Fig 39. The pieces for the JM plug.

Fig 40. The aluminium cover and cooling pipes for the JM plug.

Fig 40. The aluminium cover and cooling pipes for the JM plug.

The moderator shielding (JM) on the front face of the endcap liquid argon calorimeters

protects the inner detector from back-splash

of neutrons from the calorimeter. It is made with a mass that is as small

as possible and the total weight of this shielding is only 2x168 kg.

The moderator shielding is made of polyethylene doped

with boron carbide (B4C). The carbon makes the polyethylene black in color

and very hard. This dopant also results in a plastic that is more radiation hard

than if other boron dopants were used. This is important since the shielding

in front of the forward calorimeter is exposed to a very large dose of radiation

during the ATLAS lifetime. The density of the doped polyethylene has been measured to

be 0.990+-0.001 g/cm3 at 23oC.

1) The 2m diameter disc on the front face of the endcap

liquid argon calorimeter with a weight of 90 kg (Fig. 37);

2) The tube and plug which lines the alcove in front

of the forward calorimeter with a weight of 52 kg (Fig. 39).

Drawings of the polyethylene parts

Drawings of the aluminium cover

Drawings of the cooling system

Description of the polyethylene shielding

Test of intumescent paint

Polyethylene Agreement On Safety

More JM photos

Fig 41. The JM after installation on the endcap calorimeter.

Fig 42. Installation of scintillators on top of the JM disc.

Fig 43. The finished JM has been installed on the calorimeter.

Fig 44. The aluminium cover is painted with a special white intumescent paint.

Fig 45. Installation of the support tube.

Fig 46. One of the washers.

Fig 47. The tube and the first washer after installation.

The nose (JN) shielding, or the TX1S shielding as it is also called,

has as a purpose to support the TAS collimator and to protect ATLAS

from the radiation created in the TAS. The purpose of the TAS collimator

is to prevent the first LHC quadrupole from quenching due to the

heat created by the particles from the interactions in ATLAS. The nose

shielding is permanently installed in ATLAS and cannot as the forward

shielding be removed during shutdowns.

Washer 1. Outer diameter: 524cm, Thickness: 30.5 cm, Weight: 28 tonnes

Washer 2. Outer diameter: 524cm, Thickness: 37.6 cm, Weight: 40.5 tonnes

Washer 3. Outer diameter: 524cm, Thickness: 37.6 cm, Weight: 40.5 tonnes

Washer 4. Outer diameter: 524cm, Thickness: 37.6 cm, Weight: 40.5 tonnes

Washer 5. Outer diameter: 524cm, Thickness: 37.6 cm, Weight: 40.5 tonnes

Washer 6. Outer diameter: 415cm, Thickness: 20.0 cm, Weight: 9 tonnes

Drawings of the monobloc

Drawings of the support tube

Drawings of the cradle

Drawings of the washers

Drawing of the concrete support structure

Technical specifications and calculation reports

More JN photos

Fig 48. Front view of the monobloc and the cradle (lower right).

Fig 49. Front view of the TAS collimator and the remotely controlled

beampipe flange.

Fig 50. Back view of the TAS and the cradle.

Fig 51. The monobloc after installation.

Fig 52. Plug 1.

There are three brass shieldings inside the endcap liquid argon cryostat.

The largest one (Plug 1) has an inner diameter that is 118.2 cm, an outer

diameter that is 386.8 cm and a weight of 12 tonnes (Fig. 52). It is attached

to the back endplate of the cryostat.

Drawing of the FCAL

Drawing of Plug 1

Drawings of Plug 2

Drawing of Plug 3

Technical specifications

More LAr plug photos

Fig 53. Plug 2.

Fig 54. The forward calorimeter with Plug 3 shown as the cylinder

to the right.

CLADDING

SUMMARY OF MATERIALS

JN-Nose Shielding:

JF-Forward Shielding:

JD-Disk Shielding:

JT-Toroid Shielding:

JM-Moderator Shielding:

Calorimeter Plugs:

Total:

Reduction in new design:

Concrete

920

-

-

-

-

-

920

0

Cast Iron

744

775

6.6

110

-

-

1636

224 (JN)

Grey Steel

-

50

107

-

-

-

157

492 (JF)

Stainless Steel

-

-

14

-

-

-

14

0

Brass

-

-

42

-

-

32

74

179 (JT)

Polyethylene

-

11

1.2

5.8

0.28

-

18

55 (JF & JT)

Lead

-

-

6.3

-

-

-

6

128 (JF)

POSITIONS AND DIMENSIONS

Beampipe drawings

Overview drawing of the ATLAS beampipe

The inner detector (VI) beampipe

The inner detector (VI) beampipe cladding

The LAr calorimeter (VA) beampipe

The LAr calorimeter (VA) beampipe cladding

The VA pump

The VA fixed support to the JD

The VA rolling support

The toroid (VT) beampipe

The toroid (VT) beampipe cladding

The VT fixed support to the JTT

The forward shielding (VJ) beampipe

The forward shielding (VJ) beampipe cladding

The VJ support cone

TAS assembly drawing

The TAS beampipe

The pump in front of the TAS

The remote flange in front of the TAS

BEAMPIPE

VI

VI

VI

VA

VA

VA

VA

VA

VA

VA

VT

VT

VT

VT

VT

VT

VJ

VJ

VJ

VJ

VJ

VJ

VJ-TAS

TAS

TAS

TAS

Z POSITION

0-3550 mm

3550-3650 mm

3636-3650 mm

3650-3664 mm

3650-9000 mm

3786-3787 mm

3787-3843 mm

3843-3844 mm

3792-3838 mm

8986-9000 mm

9000-9014 mm

9000-10467 mm

10467 mm

10507 mm

10507-13207 mm

13187-13207 mm

13207-13227 mm

13207-14314 mm

14314 mm

14412 mm

14412-18499 mm

18477-18499 mm

18499-18980 mm

18980-19033 mm

19033-21110 mm

19033-20833 mm

RADIUS

29.0-29.8 mm (0.8 mm Be)

29.0-30.0 mm (1.0 mm Al)

30.0-43.0 mm (13 mm Al)

30.0-43.0 mm (13 mm SS)

29.2-30.0 mm (0.8 mm SS)

30.0-84.0 mm (54 mm SS)

83.0-84.0 mm (1 mm SS)

30.0-84.0 mm (54 mm SS)

48.0-71.0 mm (23 mm Ti)

30.0-43.0 mm (13 mm SS)

30.0-43.0 mm (13 mm SS)

29.2-30.0 mm (0.8 mm SS)

29.2-30.2 mm (1.0 mm SS)

40.0-41.0 mm (1.0 mm SS)

40.0-41.0 mm (1.0 mm SS)

41.0-76.0 mm (35 mm SS)

41.0-76.0 mm (35 mm SS)

40.0-41.0 mm (1.0 mm SS)

40.0-41.5 mm (1.5 mm SS)

60.0-61.5 mm (1.5 mm SS)

60.0-61.5 mm (1.5 mm SS)

61.5-101.0 mm (39.5 mm SS)

-

17-120 mm (103 mm SS)

17-30 mm (13 mm Cu)

30-250 mm (220 mm Cu)

ISOLATION JACKET

4.4 mm aerogel + heater

4.4 mm aerogel + heater

-

-

4.4 mm aerogel + heater

18 mm jacket

18 mm jacket

18 mm jacket

-

-

-

4.4 mm aerogel + heater

4.4 mm aerogel + heater

4.4 mm aerogel + heater

4.4 mm aerogel + heater

-

-

4.4 mm aerogel + heater

4.4 mm aerogel + heater

4.4 mm aerogel + heater

8.4 mm aerogel + heater

-

-

-

-

-

COMMENT

Be beampipe

Al beampipe

Al flange

SS flange

SS beampipe

SS Pump shell

SS Pump shell

SS Pump shell

Ti Pump element 350g

SS flange

SS flange

SS beampipe - front

SS cone - front

SS cone - back

SS beampipe - back

SS flange

SS flange

SS beampipe - front

SS cone - front

SS cone - back

SS beampipe - back

SS flange

See figure below

SS TAS flange

Cu beampipe

Cu collimator

JD plug: R(mm)=0.01875(Z+149.33) for Z:6784-8864 mm

JT plug: R(mm)=0.01931(Z-55.54) for Z:8909-12585 mm

JFC1: R(mm)=0.00732(Z+23506) for Z:12969-18570 mm

JFC2: R(mm)=0.00747(Z+24777) for Z:12719-15799 mm

JFC3: R(mm)=0.01904(Z+166.85) for Z:15799-18530 mm

VJ cone: R(mm)=0.01920(Z-8863) for Z:14505-18605 mm

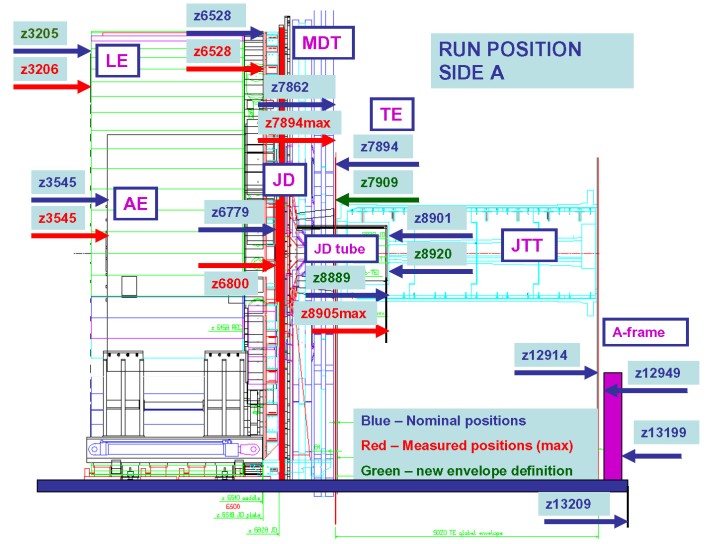

Length of endcap calorimeter is 318.5 cm. Nominal front and back of endcap calorimeter is at 354.0 cm and 672.5 cm

Nominal clearance between the back of the endcap calorimeter and the JD is 677.9 - 672.5 = 5.4 cm

Measured front of the endcap calorimeter = 354.5 cm on side A & 354.7 cm on side C

Adding 318.5 cm gives a measured back of the endcap calorimeter = 673.0 cm on side A and 673.2 cm on side C

Measured clearance between the back of the endcap calorimeter and the JD is 680.0 - 673.0 = 7.0 cm on side A

Measured clearance between the back of the endcap calorimeter and the JD is 679.8 - 673.2 = 6.6 cm on side C

Front of the ECT is at 792.9 cm.

Clearance JD hub ECT is 792.9 786.9 = 6.0 cm (nominal to nominal).

Clearance JD tube JTT is 890.9 888.9 = 2.0 cm (nominal to nominal).

Measured end of JD tube = 890.5 cm (side A) % 890.6 cm (side C).

Measured clearance JD tube JTT is 890.9 890.5 = 0.4 cm on side A (measured to nominal).

Measured clearance JD tube JTT is 890.9 890.6 = 0.3 cm on side C (measured to nominal).

The lengths of the JD tube on side C,

as measured by the surveyors,

is 2106.8+-0.6mm.

The errors here indicate the range of the measurements.

The nominal lengths of the JD tube assembly is 2105.0 mm.

Back of the ECT is at 792.9 + 495.3 = 1288.2 cm (1291.4 envelope).

Front of the JFC1 is at 1296.9 cm (1293.9 envelope).

Nominal clearance ECT JFC1 is 1296.9-1288.2 = 8.7 cm.

Nominal clearance JTT JFC1 is 1296.9-1285.0 = 11.9 cm.

Measured clearance ECT - JFC1 = 8.5 cm (side A).

Measured clearance JTT - JFC1 = 9.5 cm (side A).

Back of the JF bridge is at 1857.0 cm (ledge not included).

Back of JFC3 is at 1853.0 cm.

Front of the JN monobloc is at 1861.0 cm (surveyed position).

Nominal clearance JF bridge JN monobloc is 1861.0-1857.0 = 4.0 cm.

Nominal clearance JFC3 JN monobloc is 1861.0-1853.0 = 8.0 cm.

Measured clearance JFC1 - JN = 7.8 cm (side A) & 5.6 cm (side C).

Measured clearance JFC3 - JN = 8.7 cm - 9.5 cm (bottom - top on side C).

The lengths of the two JF bridges,

as measured by the surveyors,

are 5800.8+-0.8mm (with ledge) and 5602.0+-1.4mm (without ledge) for the first bridge

and 5801.2+-0.5mm (with ledge) and 5602.5+-0.8mm (without ledge) for the second bridge.

The errors here indicate the range of the measurements. The nominal lengths of

the JF bridge is 5801.0mm (with ledge) and 5601mm (without ledge).

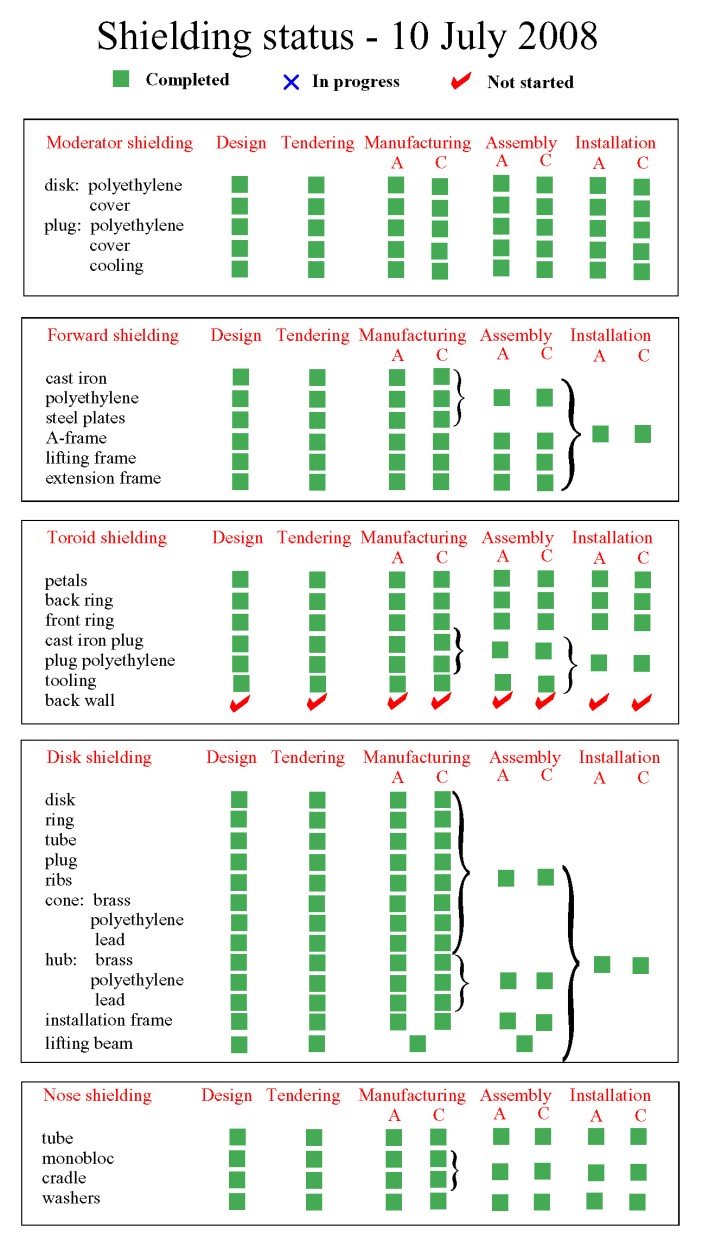

STATUS

WORKPACKAGES

Back to the ATLAS home page

Last update:

15 March 2010